Consulting Engineers

and Environmental Scientists

We are Waterman, where every project and client matters.

Creativity is what we do, and our diverse team of engineering consultants and environmental specialists innovate every day to solve complex problems, creating a better environment for people and the planet.

We think differently, and we’re harnessing our collective expertise to deliver greener, healthier and well-connected communities, networks and built environments where people and businesses thrive.

Inspired by our collaborative culture, our multidiscipline team works together to deliver optimum solutions for projects of any scale. With international reach and local expertise, we work in harmony with project teams to unlock the potential of schemes across every sector, transforming our client’s visions into reality.

We are passionate about tackling the climate emergency, and we embed climate resilience in everything we do.

“Waterman has consistently helped us innovate and stay ahead of the curve with lateral thinking and engineering approaches that have product, customer and commercial focus.”

Brett Wharton, Founder and CEO, Polestar

“Waterman has consistently helped us innovate and stay ahead of the curve with lateral thinking and engineering approaches that have product, customer and commercial focus.”

Brett Wharton, Founder and CEO, Polestar

Featured News

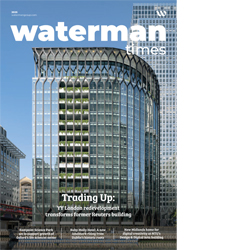

“The Waterman team has been integral in helping us create and bring to life this truly exceptional scheme that pushes the boundaries of sustainable design.”

Maxwell Shand, Co-founder, YardNine

Edenica Project

“The Waterman team has been integral in helping us create and bring to life this truly exceptional scheme that pushes the boundaries of sustainable design.”

Maxwell Shand, Co-founder, YardNine

Edenica Project